Elevator Products

Wire Rope Specification

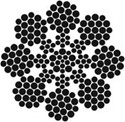

Elevator Wire Rope is specified by its diameter, construction, finish, grade, lay, preforming, and core.

Diameter is expressed in inches or millimeters and is the diameter of the smallest circle which can be circumscribed about the rope. The rope construction is generally stated as the number of outside strands and the number of wires per strand.

A Bright finish, Right Regular Lay, and Fiber Core are understood to be specified unless otherwise stated.

Prestretching, galvanized finish, left lay, lang lay, special fiber core, non-preformed wire rope, and independent wire rope core are all available for special ordering.

Technical Bulletins

Wirerope Works, Inc. (manufacturer of Bethlehem Elevator Wire Rope®) publishes service and technical bulletins on topics which affect the operation and service life of elevator wire rope. These include:

- Elevator Rope Nomenclature

- Elevator Rope Lubrication

- Elevator Rope Rouging

- Elevator Rope Slippage

- Elevator Rope Stretch

- Lubricant Build-Up

- Traction Sheave Hardness

- Tensioning

- Fatigue

- Sheaves and Grooves

- Vibration

- Moisture

- Twist and Torque

SB1. Elevator Rope Investigation #1

SB2. Elevator Investigation #2

Wire Rope Diameter

The first differentiation of wire rope is by diameter. Generally, a new wire rope is manufactured to its nominal diameter + 2 ½%.

This allows for the normal reduction of diameter experienced when a new rope is placed under load.

The Right Way

The Wrong Way

Bethlehem Fiber Core Elevator Ropes

Wirerope Works, Inc. manufactures Bethlehem Elevator Rope in a variety of diameters, constructions, lays and grades.

8 x 19 Standard Elevator Rope Technical Data

3/8” diameter and larger

1/2” diameter and larger

1/2” diameter and larger

6 x 19 Standard Elevator Rope Technical Data

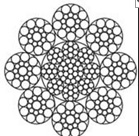

Bethlehem Liftpac Elevator Rope

Liftpac is recommended for those applications where:

- Adverse operating conditions exist, such as where loads and groove pressures are

- Reverse bends

- Fatigue breakage with minimal surface wear is the primary factor for

Liftpac is not designed to remedy poor rope performance due to worn sheaves and/or differential groove depths. Under these conditions, unsatisfactory rope performance is a result of the condition of installation.

Liftpac Elevator Rope Technical Data

FEATURES

Fatigue Resistance – The compacted strand surface minimizes the interstrand and interlayer nicking that takes place in elevator ropes, dramatically decreasing the amount

of internal breaks. This reduction of internal wire breakage can also be expressed as an increase in reserve strength. By decreasing internal breakage at the interstrand contact points, Liftpac maintains its strength longer than standard elevator rope in severe bending applications.

Abrasion Resistance – Liftpac’s compacted strand design provides improved abrasion resistance when compared with 8-strand ropes because of the increased wire and strand surfaces contacting the sheaves and drums.

Resistance To Diameter Reduction – Liftpac’s compacted design resists diameter reduction due to the higher metallic content and less core deterioration at the strand contact area.

Noise Reduction – Liftpac’s compacted surface passes smoothly over drums and sheaves, allowing for an extremely quiet running rope.

INSPECTION

Due to Liftpac’s compacted strands, its slightly flattened crown appearance should not be misconstrued as wear. Two methods may be used during inspection to make a distinction between Liftpac and a standard worn rope.

- Check the outer wires in the strand valleys. The crown wires of a worn standard rope will obviously be abraded or worn. As these wires travel into the valleys, however, they resume their normal rounded shape.

The wires in a Liftpac rope retain their die drawn state throughout the crown and valleys.

- Check the ropes at the shackles. If Liftpac is being used, the rope wires at the shackles will have the same flattened crown appearance. If the standard rope is worn, the rope wires at the shackles will be rounded.

ASME and CAN/CSA inspection and removal criteria apply.

Bethlehem Fiber Core Elevator RopesSteel Core Elevator Hoist Ropes are used where additional strength is required without increasing the diameter of the wire rope. An additional benefit of the steel core is that these ropes will exhibit somewhat reduced stretch when compared with that of fiber core ropes.

Equipment utilizing steel core elevator hoist ropes are specifically designed with the steel core in mind. Steel core ropes should not be used on equipment designed for fiber core ropes. Likewise fiber core ropes should not be used on equipment designed for steel core ropes.

Elevator Hoist Ropes with Steel Core (IWRC)

Bethlehem IWRC elevator hoist ropes

- Metric & Imperial diameters

- Manufactured to International Standards ISO 4344 or EN 12385-5

- Dual Tensile design to reduce concerns of excessive sheave wear

- Post Production Prestretch to minimize constructional stretch

- Also available in 6-Strand, Galvanized, and Lang Lay upon request

8 Strand Fiber Core Galvanized Elevator Wire Rope

8×19 Class Right Regular Lay Fiber Core

6 Strand Fiber Core Bright Elevator Wire Rope

8 and 9 Strand EHS IWRC Elevator Wire Rope

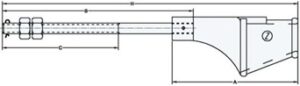

ZZWNS Elevator Shackles have been approved by MEA (City of New York, Building Department), the State of California, and TSSA, Canada.

All standard wedge shackles are painted with a black body color coded to match each wedge color for the highest safety standards.

Special wedge shackle assemblies are offered for governor rope applications.

All shackles come with wedge, two rope retaining clips, cotter pin, washer, and two (2) nuts as standard.

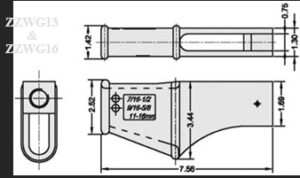

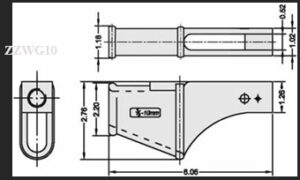

Governor Wedge Shackle Specifications

Wedge Insert Specifications

Retaining Clip Specifications

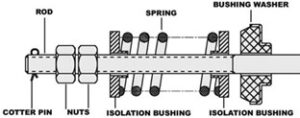

Spring Isolation Bushing Assembly

Spring Isolation Bushing Assemblies assist in providing equal tensioning of all wire rope. In addition, metal parts are isolated to provide noiseless operation between the sockets, spring, and hitch plate.

Spring Isolation Bushing Assembly

Part Number | Size |

ZZWS10 | 3/8” (10 mm) |

ZZWS13 | 7/16”-1/2” (11-13 mm) |

ZZWS16 | 9/16”-5/8” (14-16 mm) |

ZZWS19 | 11/16”-3/4” (17.5-19 mm) |

Tiller Rope

Tiller Rope is one of the most flexible wire ropes made. However, because of its fine wires, it should be used only where loads are light and abrasion and crushing are at a minimum.

The 6×42 construction is comprised of 6 strands of 6×7 fiber core around a fiber core center. Manufactured in both Phosphor Bronze or Galvanized Steel, this rope is used as a hand rope in connection with the operating device of passenger and freight elevators, as steering cable on small boats and steamers, and for industrial and mining signaling devices.

Tiller Rope should NOT be used as a hoisting rope where breakage will endanger life or property.

Galvanized Aircord

Small diameter galvanized wire rope, sometimes called Galvanized Aircord, is used in many applications including small winch lines, overhead doors, yacht rigging, and, even clothes line.

Selector Cable is a special application of 1/8” 7×19 Galvanized Aircord that has been specially lubricated and conforms to the MIL-DTL-83420 military specification.

7×19 Galvanized Aircord

Diameter (in.) | Nominal Strength (lbs) | Approx. Wt. lb/100 ft |

1/8” | 2,000 | 2.90 |

5/32” | 2,800 | 4.50 |

3/16” | 4,200 | 6.50 |

7/32” | 5,600 | 8.60 |

1/4” | 7,000 | 11.0 |

5/16” | 9,800 | 17.3 |

3/8” | 14,400 | 24.3 |

Other diameters and constructions available. | ||

Wire Rope Go-NoGo Gauge

The Go-NoGo Gauge is designed for quick checks and is not meant to replace accurate diameter measuring techniques. To use the Go-NoGo Gauge, slip the elevator rope into the corresponding diameter groove. If the rope slides in, the diameter has reduced and the rope should be retired under the criteria established by ASME specifications for diameter reduction.

Before final condemnation, use a caliper or other accurate diameter measuring tool to confirm the measurement.

- Manufactured with anodized aluminum for lightweight, durable construction

- More accurate than plastic models – diameter grooves will not wear as readily, nor will the grooves accommodate a rope whose diameter is still within acceptable limits under A17.6 specifications

- Nominal diameter provided on one side, ASME diameter reduction criteria for rope retirement on the other side

- ATL00I is Red in color and has 7 slots designed to gauge wire ropes from 3/8” to 3/4” in 1/16” increments

- ATL00KM is Blue in color and has 8 slots designed to gauge wire rope of 6 mm, 8 mm, 9.5 mm, 10 mm, 11 mm, 13 mm, 16 mm, and 19 mm diameters

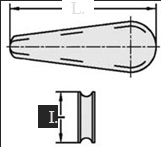

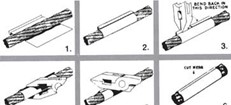

Preformed Reeving Splices

PLP Reeving Splices were designed in conjunction with the Otis Elevator Company as an aid to simplify marrying wire ropes during elevator repairs. Reeving splices hold galvanized steel cables in place, allowing old elevator ropes to be removed and replaced.

The reeving splice is an economical disposable tool that saves repair time by allowing easy passage of the married ropes over pulleys or sheaves. Applied quickly without special tools, Reeving Splices are designed to maintain a constant, positive grip, even when rope go slack.

- Designed to hold working loads from zero to 2,000 lbs

- For use on Galvanized Steel Elevator wire rope

- Patented

Reeving Splice Specifications

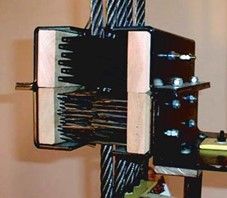

Roebling Clamp

The Roebling Clamp utilizes spiral ridges on one side of the groove to resist slippage. Properly applied, the clamp will allow two parallel ropes to share the load during shortening or tensioning applications. The clamps are designed for either 1/2” or 5/8” diameter ropes. When the included bolts are torqued to 50 ft-lbs the clamp maintains a maximum safe working load of 600 lb per rope.

Cable Bands

Cable Bands are made of pliable material indented with a groove and lock seam at one edge. Application of the band is simple, requires no special tools, and may be made in seconds with an ordinary pair of pliers.

Cable Bands are packaged 50 per box and are designed to fit a particular diameter of rope from 3/16” to 1-1/2”.

Shackle Tie Kits

Shackle Tie Kits are used to minimize the rotation of elevator rope wedge sockets under load. Once equal tension has been established, the shackles need to be secured to prevent rotation during the operation of the elevator. A short length of wire rope is laced through the shackles and the ends are joined using wire rope clips. (Local elevator codes vary as to the diameter of the wire rope required.)

The Shackle Tie Kit contains a short length of wire rope and two (2) wire rope clips.

Wire Rope Cleaner

The WRC-2000 Wire Rope Cleaner eliminates the need to clean elevator hoist ropes manually thus saving labor costs and down-time of the elevator. This assembly is designed to clean the elevator hoist ropes passively as the wire rope is used in the elevator’s everyday operation.

The WRC-2000 maintains the cleanliness of the wire rope without involving any moving mechanism, thereby increasing the durability and longevity of the wire rope.

Wire Rope Lubricator

The WRC-2000-LP Wire Rope Lubricator reduces the friction between the elevator ropes and machine drive sheaves, minimizes corrosion due to atmospheric and/or operating conditions, and reduces bending fatigue by allowing movement between the wires and strands.

Together with the WRC-2000 Wire Rope Cleaner, this is the ultimate in elevator rope maintenance.

Babbitt

Our superior lead alloy Babbitt is used for shackling of elevator wire ropes. The combination of lead, tin, and antimony (approx. 88/12/5 ratio) has a melting point of 475 degrees Fahrenheit.

The Babbitt pours (casts) between 725 degrees and 775 degrees Fahrenheit. At ambient temperatures the Babbitt forms an effective cone to secure the wires within the Babbitt socket cavity.

Rail Blocks

Rail Block (left) and Rail Block with Clevis (right) are used to hang the elevator car or counter weight at any position in the hoistway. The maximum, safe working load limit is 25,000 lb per pair of Rail Blocks when the bolts have been properly installed to 70 ft-lbs of torque. Rail blocks are available for three rail sizes (5/8” rail, 3/4” rail, & 1-1/8” / 1-1/4” rail).

Rail Blocks MUST be used in pairs.

Seizing Wire

Seizing Wire (sometimes called “Mousing Wire”) has a variety of uses where light-duty or temporary securement is required. The 21 gauge (0.0286” dia.) dark annealed steel wire is handy for whipping, bailing, binding, mousing, seizing, and other fastening applications.

These 1/2 lb spools contain approximately 186.5 ft of wire.

Wide-Jaw Wire Rope Caliper

- Stainless Steel Digital Caliper with 30 mm x 40 mm faces specifically designed to accurately determine wire rope diameters

- Measuring range is 0 – 150 mm (up to 6 inches)

- Accuracy is to within +/- 03 mm ( +/- 0.0012”)

- Zero setting at any position

- Convenient switch to change from inches to millimeters

- Uses SR 44 Watch Battery (included)

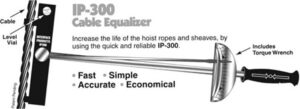

Tensionometer

- Measures the relative tension in ropes

- Allows adjustment to equal tension

- Eliminates unequal sheave groove wear, slippage and vibration

- Lengthens service life

Dynamometer

- Used to measure governor pull-through tension or empty car weight

- Accuracy at an affordable price (within 2%)

- Choice of 2,000 lb or 5,000 lb gauge

- Solid all-metal construction

- Made in the S.A.

Model Number | Range |

LM2-0900 | 0 – 900 kg |

LM2-2000 | 0 – 2000 lb |

LM2-2200 | 0 – 2200 kg |

LM2-5000 | 0 – 5000 lb |

Tractel Minifor®

The Tractel Minifor®Portable Electric Hoist has –

- Unlimited lift heights

- A complete range of electric hoist for a wide range of applications

- Rated loads of 220 lb, 660 lb and 1,000 lb which can be doubled by a sheave kit

- Unloaded wire rope freely suspended or optional rope reeler

- Pendant control

- Direct lift or sheaving kit for increased capacity

- Single-phase or three-phase power

- TR 10 & TR 30 come with blue steel box – TR 30S & TR 50 come in cardboard box

Quality & Power

- High power to weight ratio

- Aluminum alloy body

- Unlimited length of lifting wire rope

- Wire rope diameter 25 in (6.5 mm)

- 110V standard, 220V available

Safety

- Upper and lower adjustable end limit stops

- Motor integrated brake

Minifor® fitted with wire rope reeler (optional)

TR10 – TR30 Kit

TR10 – TR30 fitted with sheave block kit (optional)

Tractel Minifor®

Manual Cable Cutter

The TS-20 Handheld Hydraulic Cable Cutter is portable, lightweight, and designed to perform for years in the toughest field conditions. This cutter can be used in many applications. However, do not use for telephone & lead sheathed cable, chain, or EHS grade Guy Wire.

TS-20 Handheld Hydraulic Cutter

Impact Cable Cutter

Actuated by striking with a hammer, these portable Impact Cable Cutters are simple to operate and do a superior cutting job with just a few blows. They are precision engineered to deliver a cut without affecting the original roundness of the rope. The blades and dies are made of heat-treated tool steel ground to close tolerances. A firm base is required for operation of the cutter.

ALWAYS WEAR SAFETY GOGGLES AND FOLLOW ALL SAFETY INSTRUCTIONS WHEN OPERATING THE IMPACT CABLE CUTTER.

Model | Capacity | Height | Base | Weight |

1 | 5/8” | 6” | 3-1/2” | 7 lb |

1A | 1-1/16” | 7” | 6-1/4” | 15 lb |

2 | 1-1/2” | 9” | 7-3/4” | 28 lb |

Hydraulic Cable Cutter

The Pell Hydrashear Hydraulic Cable Cutter is a self-contained hydraulic cable cutter designed to give a clean cut with minimum effort. Just pump the handle… no outside power required.

The blades and dies are made of heat-treated tool steel ground to close tolerances. This means a long life for the blades and provides superior performance.

Hydraulic cutters are available in three sizes and capacities:

- Model W-075 has a 3/4” capacity

- Model P-1125 has a 1-1/8” capacity

- Model C-1750 has a 1-3/4” capacity

Klein Parallel-Jaw Grip

The 1671-10 Parallel-Jaw Grip has:

- Longer jaws to achieve a firm hold, reducing the possibility of slippage and damage to the cable

- A design which includes a latch, plus a large diameter eye to accommodate large hooks on hoists, winches, and tackle blocks

- A latch, when closed, that helps maintain cable position in the grip jaws

Tractel Wire Rope Gripper

The Tractel Wire Rope Gripper with a self-gripping jaw will hold a wire rope at any point along its length or take up the tension while fixing or adjusting the slack end.

- Light alloy body

- Complete with shackle for anchoring

- Spring-operated jaw for automatic gripping

- Breech loading

Tractel Con-Klam Wire Rope Gripper

The Coni-Klam Wire Rope Gripper is held by a pair of slightly serrated jaws providing a positive lock by a self-gripping wedge.

- Manufactured in forged steel

- Breech loading

- Immediate adjustment to the required positions

- Does not damage the rope

- High safety factor